Contents

1.2 FIRST Robotics Competition

1.3 Gracious Professionalism®, a FIRST® Credo

1.6 This Document & Its Conventions

1.7 Translations & Other Versions

1.9 Question and Answer System

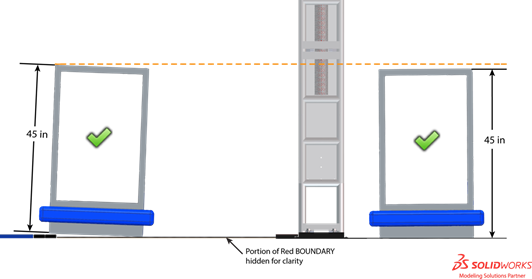

3.3.1 SHIELD GENERATOR Structure

3.3.4 SHIELD GENERATOR Lighting

3.8 The FIELD Management System

4.4.2 SHIELD GENERATOR Scoring

4.4.4 GENERATOR SWITCH Scoring

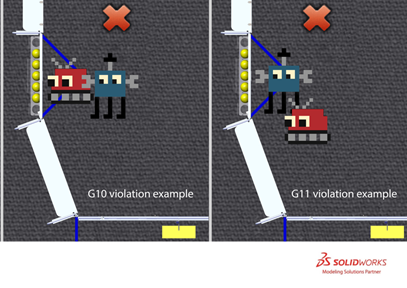

7.2.3 Zone Specific Restrictions

7.2.5 ROBOT to ROBOT Interaction

9.3 ROBOT Safety & Damage Prevention

9.4 Budget Constraints & Fabrication Schedule

9.8 Control, Command & Signals System

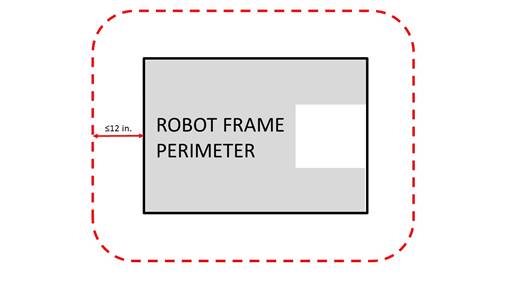

10 Inspection & Eligibility Rules

11.7.1 ALLIANCE Selection Process

11.8 Advancement Through the District Model

11.8.2 District Championship Eligibility

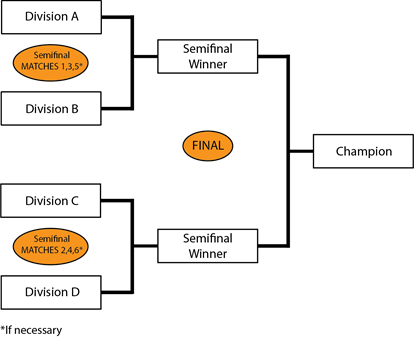

11.8.3 District Championships with Multiple Divisions

11.9 Advancement to the FIRST Championship

11.9.2 FIRST Championship Eligibility for District Teams

11.10 FIRST Championship: Additions and Exceptions

11.10.2 FIRST Championship Pit Crews

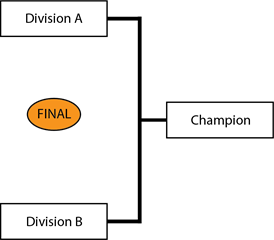

11.10.3 FIRST Championship Playoffs

![]()

FIRST® (For Inspiration and Recognition of Science and Technology) was founded by inventor Dean Kamen to inspire young people’s interest in science and technology. Based in Manchester, New Hampshire, FIRST is a 501(c)(3) not-for-profit public charity.

FIRST provides four programs:

• FIRST® Robotics Competition for grades 9-12, ages 14-18

• FIRST® Tech Challenge for grades 7-12, ages 12-18

• FIRST® LEGO® League for grades 4-8, ages 9-14 (ages 9-16 outside of North America)

• FIRST® LEGO® League Jr. for grades K-4, ages 6-10

Please visit our website: www.firstinspires.org for more information about FIRST programs.

In Memoriam

In MemoriamIn October 2019, Dr. Woodie Flowers, an innovator in design and engineering education and an incredible advisor to FIRST and supporter of our mission (see right), passed away. As thousands of heartfelt tributes to Woodie have poured in from around the world, it is clear his legacy will live on indefinitely through the gracious nature of our community and our ongoing commitment to empowering educators and building global citizens.

FIRST Robotics Competition pairs high school students with adult mentors (primarily engineers and teachers) to design and build robots that compete against one another in a high-energy environment.

This varsity Sport for the Mind™ combines the excitement of sport with the rigors of science and technology. Under strict rules, limited resources and time limits, teams of students are challenged to raise funds, design a team “brand,” hone teamwork skills, and build and program robots to perform prescribed tasks against a field of competitors. It’s as close to “real-world” engineering as a student can get.

Each January at an event known as “Kickoff,” a new, challenging game is introduced. These exciting competitions combine the practical application of science and technology with the fun, intense energy and excitement of a championship-style sporting event. Teams are encouraged to display Gracious Professionalism®, help other teams, and cooperate while competing. This is known as Coopertition®.

In 2020, FIRST Robotics Competition will reach 100,000 high-school students representing approximately 4,000 teams. Teams come from nearly every state in the United States, as well as many other countries.

FIRST Robotics Competition teams will participate in 66 Regional Competitions, 105 District Competitions, and 11 District Championships. In addition, approximately 800 teams will qualify to attend the FIRST Championship in one of two locations in April and May 2020.

This year’s game, and this manual, were presented at the 2020 FIRST Robotics Competition Kickoff on Saturday, January 4, 2020.

At the Kickoff, all teams:

• saw the 2020 game, INFINITE RECHARGESM, for the first time

• learned about the 2020 game rules and regulations

• received a Kickoff Kit that provides a starting point for robot build

Gracious Professionalism® is part of the ethos of FIRST. It’s a way of doing things that encourages high quality work, emphasizes the value of others, and respects individuals and the community.

Gracious Professionalism is not clearly defined for a reason. It can and should mean different things to everyone.

Some possible meanings of Gracious Professionalism include:

• Gracious attitudes and behaviors are win-win

• Gracious folks respect others and let that respect show in their actions

• Professionals possess special knowledge and are trusted by society to use that knowledge responsibly

• Gracious Professionals make a valued contribution in a manner pleasing to others and to themselves

In the context of FIRST, this means that all teams and participants should:

• Learn to be strong competitors, but also treat one another with respect and kindness in the process

• Avoid leaving anyone feeling as if they are excluded or unappreciated

Knowledge, pride and empathy should be comfortably and genuinely blended.

In the end, Gracious Professionalism is part of pursuing a meaningful life. When professionals use knowledge in a gracious manner and individuals act with integrity and sensitivity, everyone wins and society benefits.

The FIRST spirit encourages doing high-quality, well-informed work in a manner that leaves everyone feeling valued. Gracious Professionalism seems to be a good descriptor for part of the ethos of FIRST. It is part of what makes FIRST different and wonderful.

- Dr. Woodie Flowers, (1943 – 2019)

Distinguished Advisor to FIRST

It is a good idea to spend time going over this concept with your team and reinforcing it regularly. We recommend providing your team with real-life examples of Gracious Professionalism in practice, such as when a team loans valuable materials or expertise to another team that they will later face as an opponent in competition. Routinely highlight opportunities to display Gracious Professionalism at events and encourage team members to suggest ways in which they can demonstrate this quality themselves and through outreach activities.

At FIRST, Coopertition® is displaying unqualified kindness and respect in the face of fierce competition. Coopertition is founded on the concept and philosophy that teams can and should help and cooperate with one another even as they compete. Coopertition involves learning from teammates and mentors. Coopertition means competing always but assisting and enabling others when you can.

A Message from Woodie Flowers Award Recipients

The Woodie Flowers Award is the most prestigious mentoring award in FIRST. The award recipients as of the 2015 FIRST Championship created an important message for all FIRST Robotics Competition teams to consider as we tackle each season.

Performing at your best is important. Winning is important. This is a competition.

However, winning the right way and being proud of what you have accomplished and how you have accomplished it is more important. FIRST could create rules and penalties to cover almost any scenario or situation, but we prefer an understandable game with simpler rules that allow us to think and be creative in our designs.

We want to know that our partners and opponents are playing at their best in every match. We want to know they are playing with integrity and not using strategies based on questionable behaviors.

As you create your robots and award presentations, prepare for competition and match play, create and implement game strategies, and live your daily lives, remember what Woodie said time and time again, and let’s ‘Make your Grandmother proud.’

Woodie Flowers

Liz Calef (88)

Mike Bastoni (23)

Ken Patton (51, 65)

Kyle Hughes (27)

Bill Beatty (71)

Dave Verbrugge (5110, 67)

Andy Baker (3940, 45)

Dave Kelso (131)

Paul Copioli (3310, 217)

Rob Mainieri (812, 64, 498, 2735, 6833)

Dan Green (111)

Mark Breadner (188)

John Novak (16, 323)

Chris Fultz (234)

John Larock (365)

Earl Scime (2614)

Fredi Lajvardi (842)

Lane Matheson (932)

Mark Lawrence (1816)

Eric Stokely (258, 360, 2557, & 5295)

Glenn Lee (359)

Gail Drake (1885)

Allen Gregory (3847)

A Message from the Chief Volunteers to the FIRST Community:

“Giving Back” and “Pay It Forward” - these words are what motivates those who mentor, coach, and volunteer their time for FIRST.

We know that volunteering - whether at events or with a team - has enormous, lifelong impacts for everyone involved. Each and every student, teacher, event volunteer, mentor, coach, and family member learns and grows through each season as they interact with each other.

As you attend events and interface with the volunteers there, remember that they are giving up their most precious asset - their time - to ensure that each and every team has a fulfilling, fun, and memorable competition. Volunteers are the lifeblood of FIRST and without them, FIRST would not be where it’s at today. We encourage you to remember that “Gracious Professionalism is part of the ethos of FIRST. It's a way of doing things that encourages high-quality work, emphasizes the value of others, and respects individuals and the community.” At your next event, give a volunteer a High Five or a Fist Bump and say “Thank You”.

Volunteering at events is a rewarding experience, and we encourage everyone to take a break from the daily grind and join us at one in your community.

What makes volunteering at events so much fun:

· Seeing capable students learning and growing

· Making new friends with other awesome volunteers

· Being a part of the magic that makes an event happen

· Sharing FIRST with folks who didn’t know about it

· Taking event experiences back to your team

Please join us and walk a few miles in a volunteer’s shoes - YOURS! Come take the opportunity to Pay It Forward and Give Back; we can’t wait to see you soon. The FIRST Website is a great resource for finding events that need help and what roles you can fulfill.

Chief Field Supervisors – Paul George & Scott Goering

Chief Judge Advisors – Allen Bancroft & Cindy Stong

Chief Referees – Aidan Browne & Jon Zawislak

Chief Robot Inspectors - Al Skierkiewicz & Chuck Dickerson

Chief Volunteer Coordinators – Laurie Shimizu & Sarah Plemmons

The 2020 Game and Season Manual is a resource for all FIRST Robotics Competition teams for information specific to the 2020 season and the INFINITE RECHARGE game. Its audience will find the following detail:

• a general overview of the INFINITE RECHARGE game

• detail about the INFINITE RECHARGE playing field

• description of how to play the INFINITE RECHARGE game

• all season rules (e.g. safety, conduct, game play, inspection, etc.)

• description of how teams advance at 2020 tournaments and throughout the season

All participants should also study the Event Rules Manual as it details event rules and expectations that perpetuate from season to season. That content complements, and carries the same weight as, this document.

The intent of this manual is that the text means exactly, and only, what it says. Please avoid interpreting the text based on assumptions about intent, implementation of past rules, or how a situation might be in “real life.” There are no hidden requirements or restrictions. If you’ve read everything, you know everything.

Specific methods are used throughout this section to highlight warnings, cautions, key words and phrases. These conventions are used to alert the reader to important information and are intended help teams in constructing a robot that complies with the rules in a safe manner.

Links to other section headings in this manual and external articles appear in blue underlined text.

Key words that have a particular meaning within the context of the FIRST Robotics Competition and INFINITE RECHARGE are defined in the Glossary section and indicated in ALL CAPS throughout this document.

The rule numbering scheme uses an indication of the section in which the rule is stated plus a serial numbering system (e.g. safety rules begin with “S,” game rules begin with “G,” etc.). References to specific rules use this scheme (e.g. “S1” is the Safety Rules section).

Warnings, cautions and notes appear in blue boxes. Pay close attention to their contents as they’re intended to provide insight into the reasoning behind a rule, helpful information on understanding or interpreting a rule, and/or possible “best practices” for use when implementing systems affected by a rule.

While blue boxes are part of the manual, they do not carry the weight of the actual rule (if there is an inadvertent conflict between a rule and its blue box, the rule supersedes the language in the blue box).

Imperial dimensions are followed by comparable metric dimensions in parentheses to provide metric users with the approximate size, weight, etc. Metric conversions for non-rules (e.g. FIELD dimensions) round to the nearest whole unit, e.g. "17 in. (~43 cm)” and “6 ft. 4 in. (~193 cm).” Metric conversions in rules round such that the metric dimension is compliant with the rule (i.e. maximums round down, minimums round up). The metric conversions are offered for convenient reference only and do not overrule or take the place of the imperial dimensions presented in this manual and the field drawings (i.e. field dimensions and rules will always defer to measurements using imperial units).

Some sections and rules include colloquial language, also called headlines, in an effort to convey an abbreviated intent of the rule or rule set. This language is differentiated using bold blue text. Any disagreement between the specific language used in the rules and the colloquial language is an error, and the specific rule language is the ultimate authority. If you discover a disparity, please let us know and we will correct it.

Team resources that aren’t generally season specific (e.g. what to expect at an event, communication resources, team organization recommendations, robot transportation procedures, and award descriptions) can be found on the FIRST Robotics Competition website.

The INFINITE RECHARGE manual is originally and officially written in English and is occasionally translated into other languages for the benefit of FIRST Robotics Competition teams whose native language may not be English.

A text-based English version can be provided only for use with assistive devices for visually and hearing-impaired persons, and not for redistribution. For more information, please contact frcteamadvocate@firstinspires.org.

In the event that a rule or description is modified in an alternate version of this manual, the English pdf version as published on the FIRST Game and Season Materials webpage is the commanding version.

Team updates are used to notify the FIRST Robotics Competition community of revisions to the official season documentation (e.g. the manual, drawings, etc.) or important season news. Between Kickoff and February 21, 2020, Team Updates are posted each Tuesday and Friday. Between February 21, 2020 and April 7, 2020, Team Updates are posted each Tuesday. Team updates are posted on the INFINITE RECHARGE Game and Season Materials web page and are generally posted before 5 pm, Eastern.

Generally, Team Updates follow the following convention:

• Additions are highlighted in yellow. This is an example.

•

Deletions are indicated with a strikethrough. This is an example.

• Notes that are added for clarity or explanation for the change but are not retained as part of the manual appear in bold. This is an example.

Questions about any 2020 Game and Season Manual content and FIRST Robotics Competition Event Experience web page content may be asked to FIRST using the official Question and Answer System (i.e. “the Q&A”), which opens on January 8, 2020, 12:00 PM Eastern. Details on the Q&A can be found on the INFINITE RECHARGE Game and Season Materials web page. The Q&A is intended to help clarify rules, and sometimes the responses result in revisions to the text in the official document (which is communicated using Team Updates).

The Q&A is not a resource for

• rulings on hypothetical strategies or vague situations,

• challenging decisions made at past events, or

• design reviews of a robot system for legality.

The responses in the Q&A do not supersede the text in the manual, although every effort will be made to eliminate inconsistencies between the two. While responses provided in the Q&A may be used to aid discussion at each event, per Inspection & Eligibility Rules and REFEREE Interaction sections, REFEREES and Inspectors are the ultimate authority on rules. If you have concerns about enforcement trends by volunteer authorities, please notify FIRST at firstroboticscompetition@firstinspires.org.

Weak questions are overly broad, vague, and/or include no rule references. Some examples of questions that will not be answered in the Q&A are:

• Is this part/design legal?

• How should the REFEREE have ruled when this specific game play happened?

• Duplicate questions

• Nonsense questions

Good questions ask generically about features of parts or designs, gameplay scenarios, or rules, and often reference one or more relevant rules within the question. Some examples of questions that will likely be answered in the Q&A are:

• A device we are considering using on the ROBOT comes with purple AWG 40 wire, does this comply with R?? and R??

• We’re not sure how to interpret how Rule G?? applies if Blue ROBOT A does X and Red ROBOT B does Y, can you please clarify?

![]()

In INFINITE RECHARGESM, two alliances work to protect FIRST City from approaching asteroids caused by a distant space skirmish. Each Alliance, along with their trusty droids, race to collect and score Power Cells in order to energize their Shield Generator for maximum protection. To activate stages of the Shield Generator, droids manipulate their Control Panels after scoring a specific number of Power Cells. Near the end of the match, droids race to their Rendezvous Point to get their Shield Generator operational in order to protect the city!

During the 15 second Autonomous Period, droids follow pre-programmed instructions. Alliances score points by:

In the final 2 minutes and 15 seconds of the match, drivers take control of the droids. Alliances score points by:

The Alliance with the highest score at the end of the Match wins.

![]()

![]()

The ARENA is modular and assembled, used, disassembled, and shipped many times during the competition season. It will undergo wear and tear. The ARENA is designed to withstand rigorous play and frequent shipping. Every effort is made to ensure that ARENAs are consistent from event to event. However, ARENAs are assembled in different venues by different event staff and some small variations occur. For details regarding assembly tolerances, please refer to the 2020 ARENA Layout and Marking Diagram. Successful teams will design ROBOTS that are insensitive to these variations.

Illustrations included in this section are for a general visual understanding of the INFINITE RECHARGE ARENA, and dimensions included in the manual are nominal. Please refer to the official drawings for exact dimensions, tolerances, and construction details. The official drawings, CAD models, and drawings for low-cost versions of important elements of the INFINITE RECHARGE FIELD are posted on the 2020 INFINITE RECHARGE Game & Season Materials page on the FIRST® website.

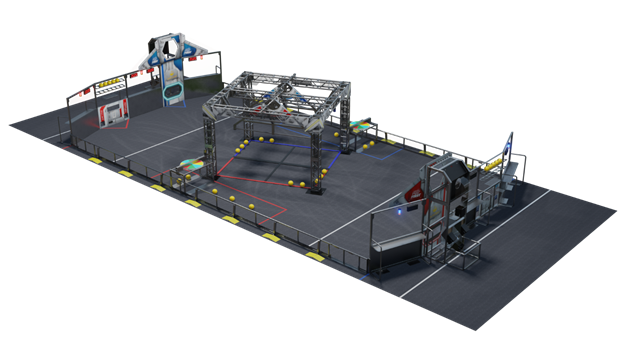

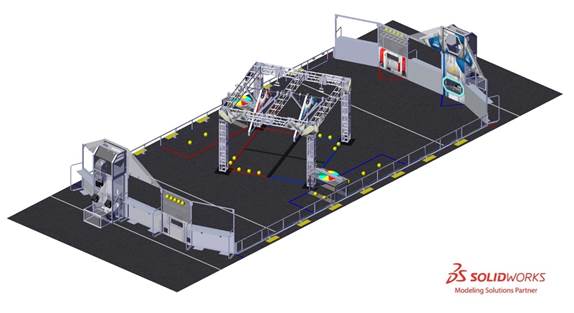

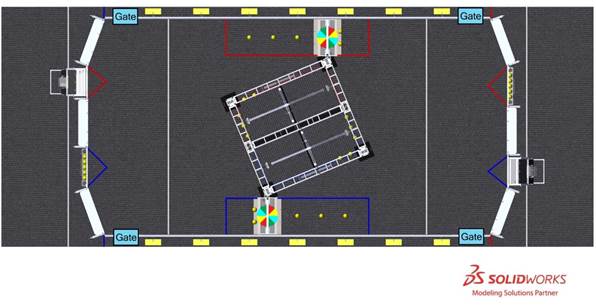

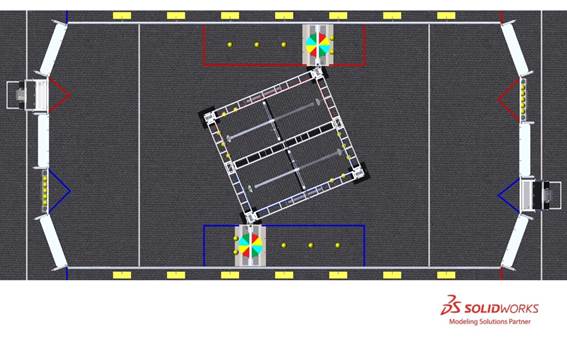

Figure 3‑1 INFINITE RECHARGE

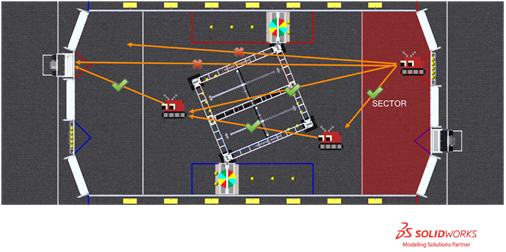

Each FIELD for INFINITE RECHARGE is 26 ft. 11¼ in. (~821 cm) by 52 ft. 5¼ in. (~1598 cm) carpeted area bound by and including the inward- and upward-facing surfaces of the guardrails and inward-facing surfaces of the ALLIANCE WALLS (except Chute surfaces and any surface beyond the face of the POWER PORT). It is populated with a SHIELD GENERATOR, TRENCHES, LOADING BAYS, and POWER PORTS.

The SHIELD GENERATOR is located in the center of the FIELD. The SHIELD GENERATOR consists of the structure, the GENERATOR SWITCHES, the BOUNDARIES, and the floor protection.

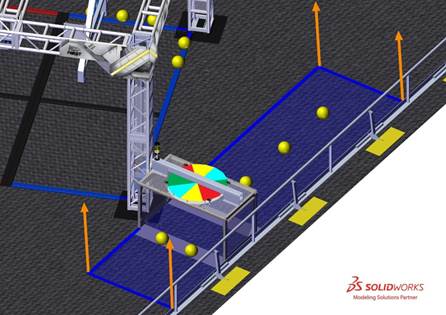

One (1) Red TRENCH and one (1) Blue TRENCH are located along the guardrail, each spanning the gap between a vertical leg of the SHIELD GENERATOR and the guardrail. Each TRENCH contains a CONTROL PANEL.

One (1) Red POWER PORT and one (1) Blue POWER PORT are located in the ALLIANCE WALLS. The Red POWER PORT is part of the Blue ALLIANCE WALL, and the Blue POWER PORT is part of the Red ALLIANCE WALL.

One (1) Red LOADING BAY and one (1) Blue LOADING BAY are located in their respective ALLIANCE WALLS.

The surface of the FIELD is low pile carpet, Shaw Floors, Philadelphia Commercial, Neyland II 20, “66561 Medallion” (please note that Neyland II carpet is not available for team purchase and the closest equivalent is Neyland III). The edge of the carpet is secured to the venue floor using 3M™ Premium Matte Cloth (Gaffers) Tape (GT2) or comparable gaffers tape.

Guardrails form the long edges of the FIELD and are a 1 ft. 7 in. (~48 cm) tall system of transparent polycarbonate supported on the top and bottom by aluminum extrusion. Guardrails, along with the ALLIANCE WALLS, prevent ROBOTS from inadvertently exiting the FIELD during a MATCH. There are four (4) gates in the guardrail that allow access to the FIELD for placement and removal of ROBOTS. The gate passthrough, when open, is 3 ft. 2 in. (~97 cm) wide. Gates are closed and shielded during the MATCH.

Figure 3‑2 Gate locations

There are two versions of guardrails and PLAYER STATIONS used for competitions. One design matches the 2020 Official FIRST FIELD Drawings & Models. The other is designed and sold by AndyMark. While the designs are slightly different, the critical dimensions, performance, and expected user experience between the two are the same. Detailed drawings for the AndyMark design are posted on the AndyMark website. All illustrations in this manual show the traditional FIELD design.

FIELD Zones and markings of consequence are described below. Unless otherwise specified, the tape used to mark lines and zones throughout the FIELD is 2-in. (~5cm) 3M™ Premium Matte Cloth (Gaffers) Tape (GT2) or comparable gaffers tape.

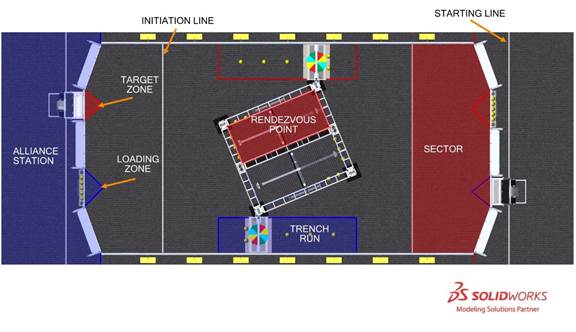

Figure 3‑3 INFINITE RECHARGE FIELD

ALLIANCE STATION: a 30-ft. (~914 cm) wide by 10 ft. 9⅛ in. (~328 cm) to 12 ft. 10⅞ in. (~393 cm) deep infinitely tall volume formed by, and including the ALLIANCE WALL, the edge of the carpet, and ALLIANCE colored tape.

INITIATION LINE: a white tape line spanning the width of the FIELD and located 10 ft. (~305 cm) from the face of PLAYER STATION 2 to the near edge of the tape. An ALLIANCE’S INITIATION LINE is located in the opponent’s SECTOR.

LOADING ZONE: a 5 ft. (~152 cm) wide, 2 ft. 6 in. (~76 cm) deep infinitely tall volume with a triangular base bounded by the LOADING BAY and ALLIANCE colored tape. The LOADING ZONE includes the ALLIANCE colored tape.

RENDEZVOUS POINT: a 5 ft. 6¾ in. (~170 cm) wide, 12 ft. 6¾ in. (~383 cm) deep, infinitely tall volume formed by the ALLIANCE colored BOUNDARIES and the black BOUNDARY pair that divides the Red and the Blue BOUNDARIES. The RENDEZVOUS POINT includes the ALLIANCE colored BOUNDARIES.

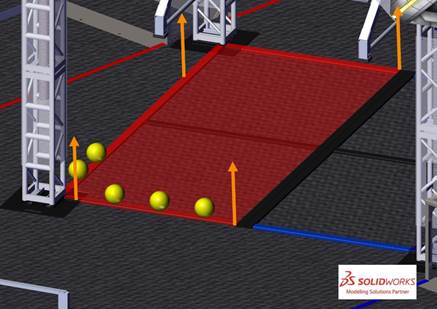

Figure 3‑4 Red RENDEZVOUS POINT

SECTOR: A 26 ft. 11¼ in. (~821 cm) wide by 10 ft. 2 in. (~310 cm) deep infinitely tall volume formed by an ALLIANCE’S ALLIANCE WALL, guardrail, and INITIATION LINE. The SECTOR includes the INITIATION LINE.

TARGET ZONE: a 4 ft. (~122 cm) wide, 2 ft. 6 in. (~76 cm) deep infinitely tall volume with a triangular base bounded by the POWER PORT and ALLIANCE colored tape. The TARGET ZONE includes the ALLIANCE colored tape.

TRENCH RUN: a 4 ft. 7 ½ in. (~141 cm) wide, 18 ft. (~549 cm) deep, infinitely tall volume that is bounded by the guardrail, the edge of the TRENCH vertical support closest to the center of the FIELD, and ALLIANCE colored tape. The TRENCH RUN includes the ALLIANCE colored tape.

Figure 3‑5 Blue TRENCH RUN

Figure 3‑6 SHIELD GENERATOR

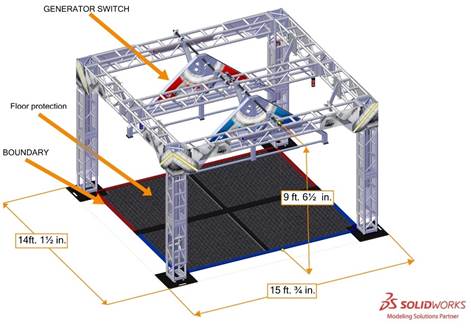

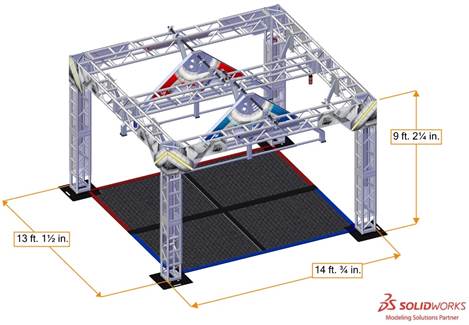

The SHIELD GENERATOR is a 14 ft. 1½ in. (~431 cm) wide, 15 ft. ¾ in. (~459 cm) deep, and 9 ft. 6½ in. (~291 cm) tall structure located in the center of the field, oriented at a 22.5 degree angle relative to the guardrails. The SHIELD GENERATOR has one (1) GENERATOR SWITCH per ALLIANCE. BOUNDARIES divide the floor of the SHIELD GENERATOR into sections. Spaces between BOUNDARIES include flooring protection to prevent floor damage. All flooring between BOUNDARIES is part of the SHIELD GENERATOR.

The SHIELD GENERATOR structure consists of 1 ft. x 1 ft. (~30 cm x ~30 cm) square truss. The truss structure is 13 ft. 1½ in. (~400 cm) wide, 14 ft. ¾ in. (~429 cm) deep, and 9 ft. 2¼ in. (~280 cm) tall. Each of the four vertical truss legs sits on a base. The baseplate extends 6 in. (~15 cm) from each square face and is ⅛ in. (~3 mm) thick.

Figure 3‑7 SHIELD GENERATOR structure

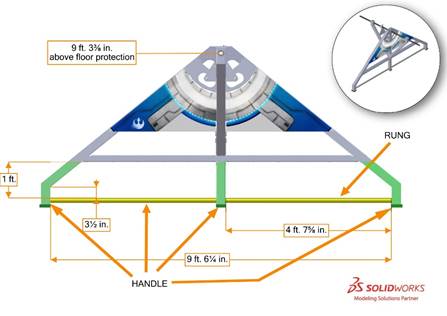

Each SHIELD GENERATOR has one (1) GENERATOR SWITCH per ALLIANCE. A GENERATOR SWITCH is a 7 ft. 6 in. (~229 cm) wide, 10 ft. 1½ in. deep (~309 cm), and 4 ft. 6 in. (~137 cm) tall assembly that swings from the top of the SHIELD GENERATOR. Each GENERATOR SWITCH has a HANDLE. The HANDLE is a structure that consists of a RUNG and the supporting structure below the horizontal beam of the GENERATOR SWITCH. A RUNG is a 1¼ in. schedule 40 aluminum pipe (1.66 in. (~4 cm) outer diameter) with two (2) exposed 4 ft. 7⅝ in. (~141 cm) long sections. The amount of clearance above the RUNG varies from a minimum of 3½ in (~9 cm) to a maximum of 12 in (~30 cm). For safety, foam corner cushions line the lowest edges of the HANDLE. The HANDLE (green and yellow) and RUNG (yellow) are highlighted in Figure 3‑8 for clarity.

Figure 3‑8 GENERATOR SWITCH

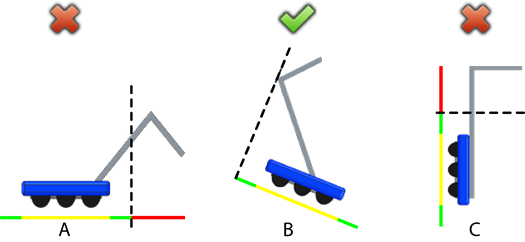

At the start of the MATCH, the top of the RUNG is parallel to and 5 ft 3 in. (~160 cm) above the floor protection carpet. The GENERATOR SWITCH can tilt and rest in different positions depending on the number and location of ROBOTS pulling on the HANDLE. For the purposes of scoring (see GENERATOR SWITCH Scoring), LEVEL is evaluated by the magnitude of its tilt as shown in Figure 3‑9. The GENERATOR SWITCH is LEVEL if the RUNG is within 8 degrees of horizontal. Hard stops prevent the GENERATOR SWITCH from rotating more than 14.5 degrees in either direction. The rotating portion of the GENERATOR SWITCH has a weight of approximately 93 lbs. (~42 kg) and a center of mass approximately 2 ft. 2 in. (~66 cm) below the center of the shaft from which it is suspended.

Figure 3‑9 GENERATOR

SWITCH range of motion.

(note: dimensions are to the top of the flooring protection carpet)

ALLIANCE colored stack lights on the SHIELD GENERATOR display information about the status of the ALLIANCE’S GENERATOR SWITCH. See SHIELD GENERATOR Lighting for more information.

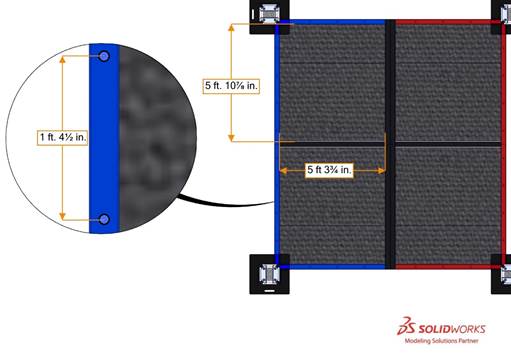

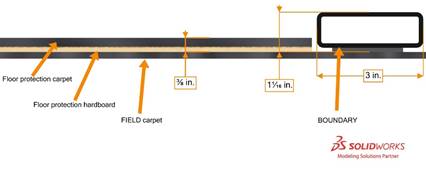

BOUNDARIES are 3 in. (~8 cm) wide, 1 in. (~3 cm) tall steel barriers that divide the area inside the SHIELD GENERATOR into four (4) equal sized rectangles that are 5 ft. 3¾ in. (~162 cm) wide by 5 ft. 10⅞ in. (~180 cm) deep. BOUNDARIES are secured to the carpet using hook fastener which increases the height to approximately 1¹⁄₁₆ in. (~3 cm). The Red and Blue BOUNDARIES feature 1-in. (~3 cm) diameter holes spaced every 1 ft 4½ in. (~42 cm) for staging of POWER CELLS. A pair of black BOUNDARIES divide the Red and Blue RENDEZVOUS POINTS. Each truss base has two shorter steel barriers, black with ALLIANCE colored tape, mounted to them. These barriers are ALLIANCE colored BOUNDARIES.

Figure 3‑10 BOUNDARY dimensions.

A layer of ⅛ in. (~3 mm) thick hardboard is installed on top of the FIELD carpet and covered with another layer of carpet to protect venue flooring. This flooring protection adds approximately ⅜ in. (~10 mm) of height to the this area.

Figure 3‑11 Floor protection cross-section

The SHIELD GENERATOR has a set of stack lights for each ALLIANCE which are enabled from the start of the END GAME until five (5) seconds after the MATCH. These lights illuminate when the corresponding GENERATOR SWITCH is LEVEL.

Each half of the SHIELD GENERATOR features three (3) ALLIANCE colored light bars inside of the truss structure.

• The first light bar, inside the vertical truss section adjacent to the ALLIANCE’S TRENCH, turns on once Stage 1 is ACTIVATED.

• The second light bar, inside the vertical truss section closest to the ALLIANCE’S POWER PORT, turns on once Stage 2 is ACTIVATED.

• The third light bar, inside the horizontal truss connecting the two (2) previous truss sections, turns on once Stage 3 is ACTIVATED.

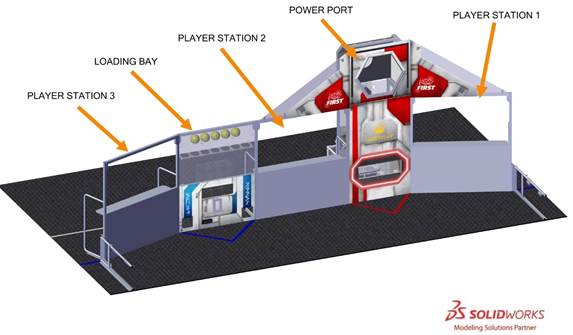

The ALLIANCE WALL is the structure that separates ROBOTS from DRIVERS, COACHES, and HUMAN PLAYERS. It consists of three (3) PLAYER STATIONS, the LOADING BAY, and the POWER PORT. ALLIANCE WALLS define the short edges of the FIELD and, along with the guardrails, prevent ROBOTS from exiting the FIELD during the MATCH.

Figure 3‑12 ALLIANCE WALL

A PLAYER STATION is one (1) of three (3) assigned positions in an ALLIANCE WALL from where a DRIVE TEAM operates their ROBOT. Each PLAYER STATION is made from a 3 ft. (~91 cm) tall diamond plate base topped with a 3 ft. 6 in. (~107 cm) tall transparent plastic sheet and a top rail. An aluminum shelf is attached to each PLAYER STATION to support an OPERATOR CONSOLE. The shelf is 5 ft. 9 in. (~175 cm) wide and 1 ft. ¼ in. (~31 cm) deep. There is a 4 ft. 6 in. (~137 cm) long by 2 in. (nominal) wide strip of hook-and-loop tape (“loop” side) along the center of the support shelf that may be used to secure the OPERATOR CONSOLE to the shelf. PLAYER STATION 1 and PLAYER STATION 3 intersect the guardrail at a 110 degree angle.

Each PLAYER STATION contains the following components for teams:

· FMS hardware and wiring: mostly located below the PLAYER STATION 2 shelf.

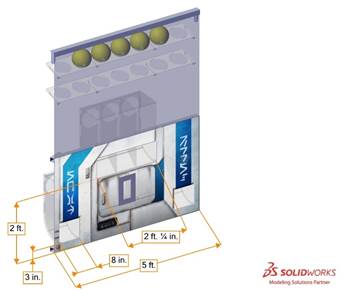

Figure 3‑13 LOADING BAY

The LOADING BAY is a 6 ft. 6 in. (~198 cm) tall by 5 ft. (~152 cm) wide structure located between PLAYER STATIONS 2 and 3. HUMAN PLAYERS deliver POWER CELLS through one (1) of the five (5) Chutes in the LOADING BAY.

There are two (2) low Chutes and three (3) high Chutes. Low Chute openings are 3 in. (~8 cm) above the carpet, and high Chute openings are 2 ft. (~61 cm) above the carpet. The high Chutes are adjacent to each other and have a combined width of 2 ft. ¼ in. (~62 cm).

The LOADING BAY also includes two (2) racks for POWER CELL storage. Each rack contains openings for seven (7) POWER CELLS. The racks are 4 ft. 11⅞ in. (~152 cm) and 5 ft. 9⅞ in. (~177 cm) above the carpet.

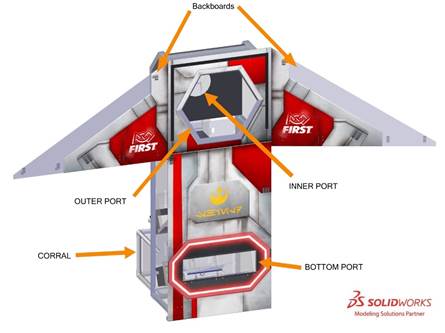

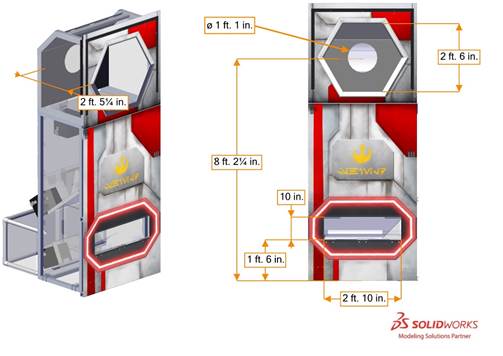

Figure 3‑14 POWER PORT

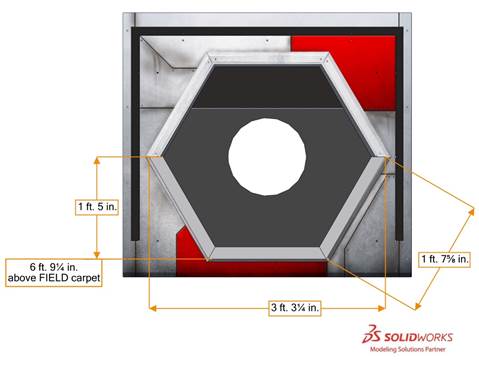

There are two (2) POWER PORTS on the FIELD. The Red POWER PORT is part of the Blue ALLIANCE WALL and the Blue POWER PORT is part of the Red ALLIANCE WALL. Each POWER PORT is a 10 ft. 2¼ in. (~310 cm) tall by 4 ft. (~122 cm) wide (excluding backboards) structure and is located between PLAYER STATIONS 1 and 2. POWER PORTS process POWER CELLS scored in its BOTTOM PORT, OUTER PORT, and INNER PORT.

The BOTTOM PORT is a 10 in. (~25 cm) tall, 2 ft. 10 in. (~86 cm) wide rectangle. The bottom edge is 1 ft. 6 in. (~46 cm) above the carpet.

The OUTER PORT is a regular hexagon that measures 2 ft. 6 in. (~76 cm) in height. The center of the OUTER PORT is 8 ft. 2¼ in. (~249 cm) above the carpet.

Figure 3‑15 POWER PORT dimensions

Each POWER PORT releases scored POWER CELLS into its CORRAL, and POWER CELLS are recycled back to the FIELD by HUMAN PLAYERS.

The POWER PORT features two (2) polycarbonate backboards, attached on either side of the OUTER PORT, to help prevent POWER CELLS from leaving the FIELD. Backboards are 6 ft. (~183 cm) wide and extend 3 ft. 8 in. (~112 cm) above the PLAYER STATIONS.

Figure 3‑16 Backboard dimensions

Around the OUTER PORT a Phillips Color Kinetics LED Light String is used to indicate the progress towards CAPACITY. The string fills symmetrically starting from the top center and proceeding out, then down. The initial nodes for each Stage (staring from the center) light up in sections that differ depending on the CAPACITY of the current Stage. The bottom four nodes on either side of the OUTER PORT always fill at a rate of one (1) node per POWER CELL scored. Examples are shown in Figure 3‑17.

Figure 3‑17 POWER PORT CAPACITY progress

A Phillips Color Kinetics LED light string around the OUTER PORT indicates CAPACITY progress. The string fills from the top center toward the side bottom nodes and is mirrored on the left and right. Nodes 1-4 and 27-30 fill per POWER CELL scored. Nodes above them light up in sections that differ depending on the CAPACITY of the current stage, as defined in Table 3‑1. A node map is shown in Figure 3‑18.

Table 3‑1 Node pattern per CAPACITY

|

CAPACITY |

Stage 1 nodes ON |

Stage 2 and 3 nodes ON |

|

1 |

14-17 |

15 and 16 |

|

2 |

11-13 and 18-20 |

|

|

3 |

9-10 and 21-22 |

14 and 17 |

|

4 |

7-8 and 23-24 |

|

|

5 |

5-6 and 25-26 |

13 and 18 |

|

6 |

4 and 27 |

|

|

7 |

3 and 28 |

12 and 19 |

|

8 |

2 and 29 |

|

|

9 |

1 and 30 |

11 and 20 |

|

10 |

|

|

|

11 |

N/A |

10 and 21 |

|

12 |

N/A |

9 and 22 |

|

13 |

N/A |

8 and 23 |

|

14 |

N/A |

7 and 24 |

|

15 |

N/A |

6 and 25 |

|

16 |

N/A |

5 and 26 |

|

17 |

N/A |

4 and 27 |

|

18 |

N/A |

3 and 28 |

|

19 |

N/A |

2 and 29 |

|

20 |

N/A |

1 and 30 |

Figure 3‑18 Light string node map

Light strings also indicate other FIELD states as shown in Table 3‑2 and Figure 3‑19.

Table 3‑2 additional POWER PORT Light States

|

Light State |

Criteria |

|

Off |

Outside of a MATCH: FIELD is MATCH ready In MATCH: current stage not ACTIVATED |

|

Green |

Head REFEREE has determined FIELD safe for humans |

|

ALLIANCE color with yellow chase pattern |

Stage has reached CAPACITY, but not ACTIVATED |

|

Entire light string is ALLIANCE color |

All stages ACTIVATED |

Figure 3‑19: Additional POWER PORT state examples

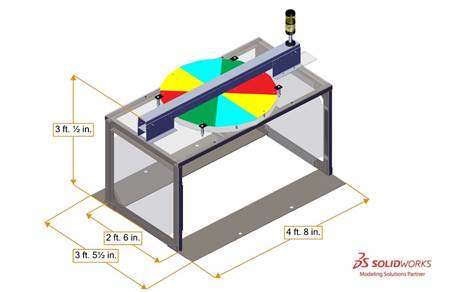

Each ALLIANCE has a TRENCH in their TRENCH RUN that spans the gap between the guardrail and SHIELD GENERATOR. On the top of each TRENCH is an ALLIANCE specific CONTROL PANEL and a yellow stack light.

Figure 3‑20 TRENCH

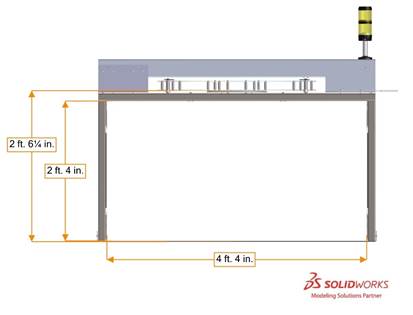

Each TRENCH is a 3 ft. ½ in. (~93 cm) tall, 4 ft. 8 in. (~142 cm) wide, and 3 ft. 5½ in. (~105 cm) deep structure that forms a 4 ft. 4 in. (~132 cm) wide, 2 ft. 4 in. (~71 cm) tall, and 2 ft. 6 in. (~76 cm) deep tunnel. Each TRENCH has two (2) ⅛ in. (~3 mm) thick baseplates. Each baseplate has two (2) 1-in. (~3cm) diameter holes used to stage POWER CELLS. Holes are 1 ft. 6½ in. (~47 cm) apart.

Figure 3‑21 TRENCH dimensions

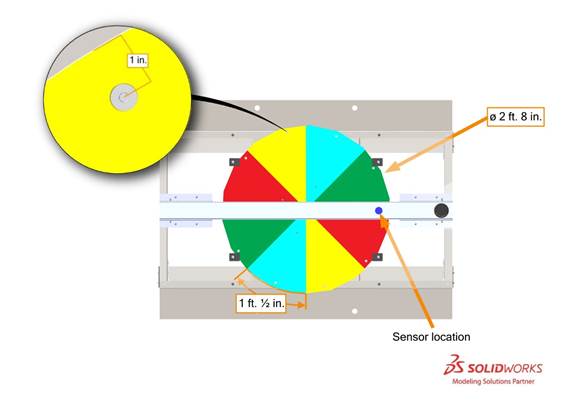

A CONTROL PANEL is centered on the top of each TRENCH. The CONTROL PANEL is a 2 in. (~5 cm) tall, 2 ft. 8 in. (~81 cm) diameter disk constructed of two pieces of ¼ in. (~6 mm) thick polycarbonate, spaced apart by ten ½ in. (~13 mm) diameter metal spacers at regular intervals. The centers of the spacers are located 1 in. (~3 cm) in from the outer perimeter of the CONTROL PANEL. The bottom edge of the CONTROL PANEL is located 2 ft. 6¼ in. (~77 cm) above the carpet.

Figure 3‑22 TRENCH and CONTROL PANEL dimensions

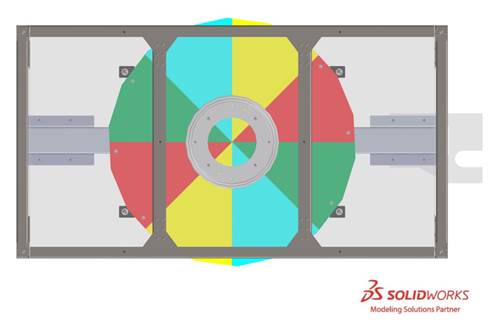

The CONTROL PANEL is divided into 8 equal size wedges. Wedges are red, green, blue, and yellow (see Table 3‑3 for CMYK values) and visible from above and below the CONTROL PANEL. Colors are arranged as shown in Figure 3‑23 and line up top and bottom. The arc length of each wedge is 1 ft. ½ in. (~32 cm). Fasteners in the CONTROL PANEL create holes in the colored wedges.

Table 3‑3: CONTROL PANEL color chart

|

CONTROL PANEL color |

Cyan |

Magenta |

Yellow |

Black |

|

Blue |

100 |

0 |

0 |

0 |

|

Green |

100 |

0 |

100 |

0 |

|

Red |

0 |

100 |

100 |

0 |

|

Yellow |

0 |

0 |

100 |

0 |

Figure 3‑23 TRENCH bottom view

A swatch of identical material and colors to those on the CONTROL PANEL is in each Black Tote of the 2020 Kickoff Kit. The CONTROL PANEL is attached to the TRENCH via a 12 in. (~30 cm) Lazy Susan Bearing (Triangle Manufacturing PN: 12D10346). An identical Lazy Susan Bearing is in each Black Tote of the 2020 Kickoff Kit.

Each CONTROL PANEL has two (2) requirements in order to ENERGIZE the SHIELD GENERATOR, see CONTROL PANEL Scoring for complete details on game play.

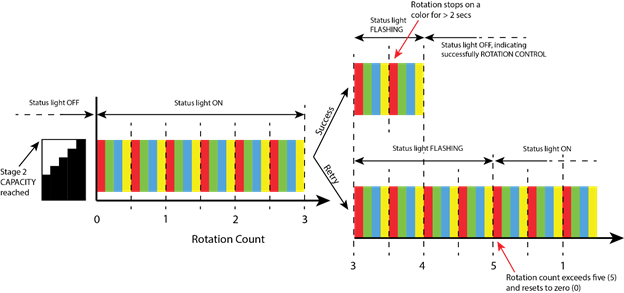

· ROTATION CONTROL: Rotate CONTROL PANEL at least three (3) (but no more than five (5)) complete revolutions in the same direction. If the CONTROL PANEL is rotated more than five (5) complete revolutions, the count resets to zero (0). The TRENCH light turns on once Stage 2 CAPACITY is reached (i.e. the CONTROL PANEL is ready for ROTATION CONTROL).

A CONTROL PANEL spun faster than 60 revolutions per minute may cause FIELD damage. For more details see MATCH Replays.

Figure 3‑24 CONTROL PANEL ROTATION CONTROL example

· POSITION CONTROL: Rotate CONTROL PANEL so a specified color aligns with the sensor for at least five (5) seconds. Once either ALLIANCE reaches Stage 3 CAPACITY, FMS relays a specified color (randomly selected by FMS and one (1) of the three (3) colors not currently read by the ALLIANCE’S TRENCH color sensor) to all OPERATOR CONSOLES simultaneously. The specified color may not be the same for both ALLIANCES. See Table 3‑4 for details on how the TRENCH light is used during POSTION CONTROL.

Specific details on the format of the data can be found on the 2020 FRC Control System website.

In the unlikely event that the sensor isn’t currently reporting one (1) of the four (4) colors when Stage 3 reaches CAPACITY (e.g. the sensor is positioned where two (2) color wedges meet), FMS will randomly select the specified color from one (1) of the four (4) colors.

Each TRENCH has a yellow stack light to indicate CONTROL PANEL status.

Table 3‑4 TRENCH light status

|

Light State |

SHIELD GENERATOR Stage |

Criteria |

|

Off |

1, 2, or 3 |

Stage not at CAPACITY or Stage 3 ACTIVATED |

|

Solid |

2 or 3 |

The POWER PORT is at CAPACITY, the CONTROL PANEL is ready for use |

|

Flashing |

2 |

The CONTROL PANEL has rotated the required number for ROTATION CONTROL, but has not yet continuously read a single color for two (2) seconds |

|

3 |

The CONTROL PANEL has read the required color for POSITION CONTROL for at least three (3) seconds and less than five (5) seconds1 |

1 If a color change is detected during the two (2) second period when the stack light is flashing, the light returns to solid and the color detection timer resets to zero (0).

Figure 3‑25 POWER CELL

INFINITE RECHARGE is played with POWER CELLS. A POWER CELL is a yellow 7 in. (~18 cm) diameter Medium Bounce Dino-Skin foam ball. The FIRST logo is printed on each ball in black ink. The ball is made by Flaghouse (PN 1892 YEL) and sold by AndyMark (PN AM-4200). A POWER CELL is in each Black Tote of the 2020 Kickoff Kit.

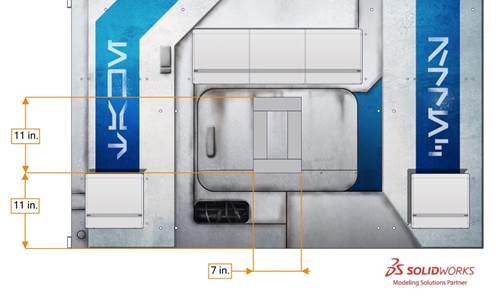

Vision targets made from 2 in. (~5 cm) wide strips of 3M 8830 ScotchliteTM Reflective Material are located on the POWER PORTS and LOADING BAYS. On the POWER PORT, they target the location of the INNER and OUTER PORTS and trace the bottom perimeter of the OUTER PORT. The target has an overall height of 1 ft. 5 in. (~43 cm), and a width of 3 ft. 3¼ in. (~100 cm). The bottom of the target is 6 ft. 9¼ in. (~206 cm) above the carpet. A strip of 3M 8830 ScotchliteTM Reflective Material is in FIRST Choice.

Figure 3‑26 POWER PORT Vision Target

The LOADING BAY target is a 7 in. (~18 cm) wide by 11 in. (~28 cm) tall rectangle. The target is centered on the width of the LOADING BAY and located 11 in. (~28 cm) above the carpet.

Figure 3‑27 LOADING BAY Vision Target

The Field Management System (FMS) is the electronics core responsible for sensing and controlling the FIRST Robotics Competition FIELD. The FMS encompasses all FIELD electronics, including computers, REFEREE touchscreens, wireless access point, sensors, stack lights, E-Stops, etc.

When a DRIVE TEAM connects the Ethernet cable from their assigned PLAYER STATION to their OPERATOR CONSOLE, the Driver Station software on the OPERATOR CONSOLE computer will communicate with FMS. Once connected, the open ports available are described in Table 3‑5.

Table 3‑5 Open FMS Ports

|

Port |

Designation |

Bi-directional? |

|

UDP/TCP 1180-1190 |

Camera data from the roboRIO to the Driver Station when the camera is connected the roboRIO via USB |

Yes |

|

TCP 1735 |

SmartDashboard |

Yes |

|

UDP 1130 |

Dashboard-to-ROBOT control data |

Yes |

|

UDP 1140 |

ROBOT-to-Dashboard status data |

Yes |

|

HTTP 80 |

Camera connected via switch on the ROBOT |

Yes |

|

HTTP 443 |

Camera connected via switch on the ROBOT |

Yes |

|

UDP/TCP 554 |

Real-Time Streaming Protocol for h.264 camera streaming |

Yes |

|

UDP/TCP 1250 |

CTRE Diagnostics Server |

Yes |

|

UDP/TCP 5800-5810 |

Team use |

Yes |

Teams may use these ports as they wish if they do not employ them as outlined above (e.g. TCP 1180 can be used to pass data back and forth between the ROBOT and the Driver Station software if the team chooses not to use the camera on USB). Note that ROBOT code cannot be deployed while connected to the FMS. Additional information about the FMS may be found in the FMS Whitepaper.

The FMS provides the specified color for POSITION CONTROL to the Driver Station software, see CONTROL PANEL for additional details.

While FMS provides the specified color for POSITION CONTROL to each team’s Driver Station, teams must write the necessary ROBOT code to make use of the information during a MATCH.

FMS alerts participants to milestones in the MATCH using audio cues detailed in Table 3‑6. Please note that audio cues are intended as a courtesy to participants and not intended as official MATCH markers. If there is a discrepancy between an audio cue and the FIELD timers, the FIELD timers are the authority.

Table 3‑6 Audio cues

|

Event |

Timer Value |

Audio Cue |

|

MATCH Start |

0:15 (for AUTO) |

“Cavalry Charge” |

|

AUTO Ends |

0:00 (for AUTO) |

“Buzzer” |

|

TELEOP Begins |

2:15 |

“Three Bells” |

|

ENDGAME warning |

0.30 |

“Imperial Alarm” |

|

MATCH End |

0:00 |

“Buzzer” |

|

MATCH Stopped |

n/a |

“Foghorn” |

|

ROTATION CONTROL complete |

n/a |

“Whirring” |

|

POSITION CONTROL complete |

n/a |

“Charging Up” |

![]()

![]()

During INFINITE RECHARGESM, two (2) ALLIANCES (an ALLIANCE is a cooperative of up to four (4) FIRST Robotics Competition teams) play MATCHES, set up and executed per the details described below.

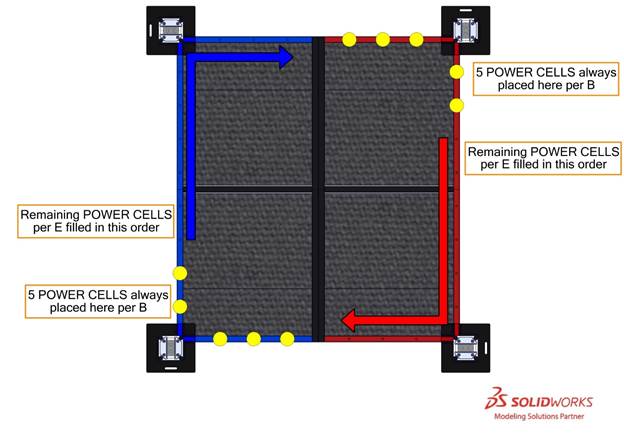

Forty-eight (48) POWER CELLS are staged as follows:

A. five (5) POWER CELLS in each of the two (2) TRENCH RUNS

i. two (2) POWER CELLS are placed on each of the TRENCH baseplates further away from the center of the FIELD.

ii. three (3) POWER CELLS are placed centered in the width of each TRENCH RUN, spaced at 3-ft. (~91 cm) intervals. Small rings are used to keep them in place prior to the start of a match. Rings are ⅛ in. (~3 mm) thick, 1¾ in. (~4 cm) diameter O-rings (McMaster Item#: 9452K63). Rings are secured to the carpet by tape.

B. five (5) POWER CELLS placed on the BOUNDARIES inside each ALLIANCE’S RENDEZVOUS POINT as shown in Figure 4‑2.

C. five (5) POWER CELLS on the racks in each ALLIANCE STATION’S LOADING BAY,

D. each of the three (3) teams may preload up to three (3) POWER CELLS in their ROBOT, such that they are fully and solely supported by that ROBOT, and

E. remaining POWER CELLS (zero (0) to nine (9) per ALLIANCE, depending on decisions made in D) in the holes on the BOUNDARIES in the corresponding ALLIANCE’S RENDEZVOUS POINT as shown in Figure 4‑2.

Figure 4‑1: POWER CELL Setup

Figure 4‑2: POWER CELL setup on BOUNDARIES

Each TEAM stages their ROBOT such that at least part of its BUMPERS are intersecting the infinite vertical volume created by the corresponding ALLIANCE’S INITIATION LINE.

If order placement matters to either or both ALLIANCES, the ALLIANCE must notify the Head REFEREE during setup for that MATCH. Upon notification, the Head REFEREE will require ALLIANCES to alternate placement of all ROBOTS. In a Qualification MATCH, ROBOTS are placed in the following order: Red Station 1 ROBOT, Blue Station 1 ROBOT, Red Station 2 ROBOT, Blue Station 2 ROBOT, Red Station 3 ROBOT, Blue Station 3 ROBOT. In a PLAYOFF MATCH, the same pattern is applied, but instead of Blue ALLIANCE placing last, the higher seeded ALLIANCE (regardless of color) places last.

DRIVERS, COACHES, and HUMAN PLAYERS stage behind the STARTING LINE inside their ALLIANCE STATION. TECHNICIANS stage in the event-designated area near the FIELD.

The first phase of each MATCH is called Autonomous (AUTO) and consists of the first fifteen (0:15) seconds. During AUTO, ROBOTS operate without any DRIVE TEAM control or input. ROBOTS attempt to score POWER CELLS in POWER PORTS, retrieve additional POWER CELLS from around the FIELD, and exit the infinite vertical volume created by the corresponding ALLIANCE’S INITIATION LINE any time before the end of the phase.

The second phase of each MATCH is called the Teleoperated Period (TELEOP) and consists of the remaining two minutes and fifteen seconds (2:15). During this phase, DRIVERS remotely operate ROBOTS to retrieve and score POWER CELLS in goals and manipulate CONTROL PANELS to ACTIVATE different stages of the SHIELD GENERATOR.

The final thirty (0:30) seconds of TELEOP is the ENDGAME, during which ROBOTS attempt to ENERGIZE the SHIELD GENERATOR.

ALLIANCES are rewarded for accomplishing various actions through the course of a MATCH, including ROBOT movement during AUTO, scoring POWER CELLS in POWER PORTS, manipulating CONTROL PANELS, ACTIVATING stages of the SHIELD GENERATOR, ENERGIZING the SHIELD GENERATOR, and winning or tying MATCHES.

Rewards are granted via either MATCH points (which contribute to the ALLIANCE’S MATCH score) or Ranking Points (which increase the measure used to rank teams in the Qualification Tournament). Such actions, their criteria for completion, and their point values are listed in Table 4‑2.

All scores, except ENDGAME bonuses, are assessed and updated throughout the MATCH.

ALLIANCES generate energy by scoring POWER CELLS into one of three (3) openings of their POWER PORT. To be considered scored, the POWER CELL must pass through the BOTTOM, OUTER, or INNER PORTS and exit through the respective scoring sensors during the MATCH or within five (5) seconds after the MATCH (regardless of how many POWER CELLS are being processed after the end of the MATCH).

If a POWER CELL becomes jammed in the BOTTOM, INNER, or OUTER PORT, credit for the jammed POWER CELL is granted in the period during which the POWER CELL became stuck.

Lights on the POWER PORT indicate progress towards the CAPACITY of the current Stage of the SHIELD GENERATOR. See POWER PORT for more details.

The final assessment of POWER CELLS scored in POWER PORTS is made five (5) seconds after the ARENA timer displays zero (0) following AUTO and TELEOP, respectively.

POWER CELLS scored during the five (5) seconds after the ARENA timer displays zero (0) following AUTO earn AUTO points and, if STAGE 1 has been ACTIVATED, count towards STAGE 2 CAPACITY.

The SHIELD GENERATOR stores energy generated by scored POWER CELLS. ALLIANCES work to make the SHIELD GENERATOR OPERATIONAL and ENERGIZED in order to protect FIRST City.

The SHIELD GENERATOR has three (3) stages that need to be charged to CAPACITY and ACTIVATED consecutively. CAPACITY is the number of POWER CELLS, defined in Table 4‑1, that must be scored to charge each stage. Each POWER CELL, regardless of the POWER PORT opening in which it scores, counts equally toward CAPACITY.

Table 4‑1: SHIELD GENERATOR ACTIVATION requirements

|

Stage |

CAPACITY |

ACTIVATED when… |

|

1 |

9 |

nine (9) POWER CELLS are scored & TELEOP has begun |

|

2 |

20 |

twenty (20) POWER CELLS are scored in Stage 2 & ROTATION CONTROL is complete |

|

3 |

20 |

twenty (20) POWER CELLS are scored in Stage 3 & POSITION CONTROL is complete |

As the season progresses, the CAPACITY required for each Stage of the SHIELD GENERATOR may increase. While Stage CAPACITY will not change between weeks of Regional or District Competition play, the Stage CAPACITY may be changed for District Championship and/or FIRST Championship play. Teams will be notified of changes in Stage CAPACITY no later than the scheduled Team Update prior to the date of the event.

POWER CELLS scored after a stage is at CAPACITY generate MATCH points but do not contribute to the next stage’s CAPACITY. POWER CELLS scored after Stage 3 is ACTIVATED continue to generate MATCH points.

SHIELD GENERATOR lights indicate ACTIVATED Stages. See SHIELD GENERATOR Lighting for more details.

CONTROL PANELS ACTIVATE SHIELD GENERATOR stages two (2) and three (3) as described in CONTROL PANEL. CONTROL PANEL requirements (i.e. ROTATION CONTROL AND POSITION CONTROL) are not evaluated until the respective stage is at CAPACITY. A stage may be ACTIVATED once it reaches CAPACITY, and a stage must be ACTIVATED before the next stage can begin charging.

Once all three (3) stages are ACTIVATED, the SHIELD GENERATOR is ENERGIZED (the SHIELD GENERATOR does not need to be OPERATIONAL to be ENERGIZED and vice versa.)

ALLIANCES use their GENERATOR SWITCH to earn MATCH Points and make the SHIELD GENERATOR OPERATIONAL.

A ROBOT is considered PARKED if, five (5) seconds after the ARENA timer displays zero (0) following TELEOP, it is fully supported (either directly or transitively) by the SHIELD GENERATOR and not in contact with any carpet outside its ALLIANCE’S RENDEZVOUS POINT, but without having met the criteria for HANGING.

A ROBOT is considered HANGING if, five (5) seconds after the ARENA timer displays zero (0) following TELEOP, it is fully supported (either directly or transitively) by its GENERATOR SWITCH.

A GENERATOR SWITCH is considered LEVEL if, five (5) seconds after the ARENA timer displays zero (0) following TELEOP, both following criteria are met:

The final assessment of a LEVEL GENERATOR SWITCH and HANGING or PARKED ROBOTS is made five (5) seconds after the ARENA timer displays zero (0) following TELEOP, at which point the Audience Display stops updating and the lights on the SHIELD GENERATOR flash three (3) times.

The SHIELD GENERATOR is considered to be OPERATIONAL when the ALLIANCE’S ENDGAME SCORE is ≥ 65 points.

Point values for tasks in INFINITE RECHARGE are detailed in Table 4‑2.

Table 4‑2: Point Values

|

Award |

Awarded for… |

AUTO |

TELEOP |

Qual. |

|

INITIATION LINE |

exit the infinite vertical volume created by the corresponding ALLIANCE’S INITIATION LINE any time before the end of AUTO (per ROBOT) |

5 |

- |

- |

|

POWER CELLS |

scored in BOTTOM PORT |

2 |

1 |

- |

|

scored in OUTER PORT |

4 |

2 |

- |

|

|

scored in INNER PORT |

6 |

3 |

- |

|

|

CONTROL PANEL |

ROTATION CONTROL |

- |

10 |

- |

|

POSITION CONTROL |

20 |

|||

|

ENDGAME Points |

HANG (per ROBOT) |

- |

25 |

- |

|

PARK (per ROBOT) |

- |

5 |

- |

|

|

LEVEL with 1-3 ROBOTS HANGING (per ALLIANCE) |

|

15 |

|

|

|

SHIELD GENERATOR OPERATIONAL |

earning at least sixty-five (65) ENDGAME points |

|||

|

SHIELD GENERATOR ENERGIZED |

- |

- |

1 Ranking Point |

|

|

Tie |

Completing a MATCH with the same number of points as your opponent |

- |

- |

1 Ranking Point |

|

Win |

Completing a MATCH with more points than your opponent |

- |

- |

2 Ranking Point |

An ALLIANCE can earn up to four (4) Ranking Points (RP) per Qualification MATCH, as described in Table 4‑2. There are no RP, or comparable point bonuses, in Playoff MATCHES.

Upon a rule violation, one or more of the penalties listed in Table 4‑3 will be assessed.

Table 4‑3 Rule violations

|

Penalty |

Description |

|

FOUL |

a credit of three (3) points towards the opponent’s MATCH score |

|

TECH FOUL |

a credit of fifteen (15) points toward the opponent’s MATCH score |

|

YELLOW CARD |

|

|

RED CARD |

|

|

DISABLED |

|

|

DISQUALIFIED |

Some rule violations escalate if the REFEREE determines an action was “repeated.” While there’s no official FIRST Robotics Competition definition of repeated, it’s meant to apply to rule violations that occur more than once within a MATCH.

The official FIRST Robotics Competition definition of momentary is fewer than three (3) seconds. The intent of using this word is to provide a reference for our community. It is not the intent for REFEREES to provide a count for these time periods.

See YELLOW and RED CARDS for additional details.

There are several styles of violation wording used in this manual. Below are some example violations and a clarification of the way the violation would be assessed. The examples shown do not represent all possible violations, but rather a representative set of combinations.

Table 4‑4: Violation Examples

|

Example Violation |

Expanded Interpretation |

|

FOUL |

Upon violation, a FOUL is assessed against the violating ALLIANCE |

|

TECH FOUL and YELLOW CARD |

Upon violation, a TECH FOUL is assessed against the violating ALLIANCE. After the MATCH, the Head REFEREE presents the violating team with a YELLOW CARD. |

|

Upon violation, a FOUL is assessed against the violating ALLIANCE. If the secondary condition is additionally met at any point while still in violation of the rule, in this case contact is made with an opponent ROBOT, a TECH FOUL is additionally assessed against the violating ALLIANCE. |

|

|

FOUL per additional POWER CELL. If egregious, YELLOW CARD |

Upon violation, a number of FOULS are assessed against the violating ALLIANCE equal to the number of additional POWER CELLS beyond the permitted quantity. Additionally, if the REFEREES determine that the action was egregious, the Head REFEREE presents the violating team with a YELLOW CARD after the MATCH. |

|

TECH FOUL, plus an additional TECH FOUL for every five (5) seconds in which the situation is not corrected |

Upon violation, a TECH FOUL is assessed against the violating ALLIANCE and the REFEREE begins to count. Their count continues until the criteria to discontinue the count are met, and for each five (5) seconds within that time, an additional TECH FOUL is assessed against the violating ALLIANCE. A ROBOT in violation of this type of rule for fifteen (15) seconds would receive a total of four (4) TECH FOULS (assuming no other rules were simultaneously being violated). |

|

After the MATCH, the Head REFEREE presents the violating ALLIANCE with a RED CARD in the following fashion: a) In a PLAYOFF MATCH, a single RED CARD is assessed to the ALLIANCE. b) In all other scenarios, each team on the ALLIANCE is issued a RED CARD. |

A DRIVE TEAM is a set of up to five (5) people from the same FIRST Robotics Competition team responsible for team performance for a specific MATCH. There are four (4) specific roles on a DRIVE TEAM which ALLIANCES can use to assist ROBOTS with INFINITE RECHARGE.

The intent of the definition of DRIVE TEAM and DRIVE TEAM related rules is that, barring extenuating circumstances, the DRIVE TEAM consists of people who arrived at the event affiliated with that team and are responsible for their team’s and ROBOT’S performance at the event (this means a person may be affiliated with more than one (1) team). The intent is not to allow teams to “adopt” members of other teams for strategic advantage for the loaning team, borrowing team, and/or their ALLIANCE (e.g. an ALLIANCE CAPTAIN believes one of their DRIVERS has more experience than a DRIVER on their 1st pick, and the teams agree the 1st pick team will “adopt” that DRIVER and make them a member of their DRIVE TEAM for Playoffs).

The definition isn’t stricter for two (2) main reasons. First, to avoid additional bureaucratic burden on teams and event volunteers (e.g. requiring that teams submit official rosters that Queuing must check before allowing a DRIVE TEAM into the ARENA). Second, to provide space for exceptional circumstances that give teams the opportunity to display Gracious Professionalism (e.g. a bus is delayed, a COACH has no DRIVERS, and their pit neighbors agree to help by loaning student DRIVERS as temporary members of the team until their bus arrives).

Table 4‑5 DRIVE TEAM roles

|

Role |

Description |

Max./ DRIVE TEAM |

Criteria |

|

COACH |

1 |

Pre-college student or adult mentor Must wear “COACH” button |

|

|

DRIVER |

3 |

Pre-college student Must wear one (1) of the three (3) “DRIVE TEAM” buttons |

|

|

HUMAN PLAYER |

|||

|

TECHNICIAN |

a resource for ROBOT troubleshooting, setup, and removal from the FIELD |

1 |

Pre-college student Must wear “TECHNICIAN” button |

The TECHNICIAN provides teams with a technical resource for pre-MATCH setup, ROBOT connectivity, OPERATOR CONSOLE troubleshooting, and post-MATCH removal of the ROBOT. Some pre-MATCH responsibilities for the TECHNICIAN may include, but are not limited to:

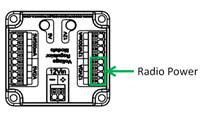

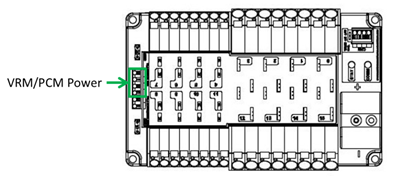

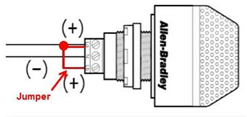

· location of the ROBOT radio, its power connection, and understanding of its indicator lights

· location of the roboRIO and understanding of its indicator lights

· username and password for the OPERATOR CONSOLE

· restarting the Driver Station and Dashboard software on the OPERATOR CONSOLE

· changing the bandwidth utilization (e.g. camera resolution, frame rate, etc.)

· changing a battery

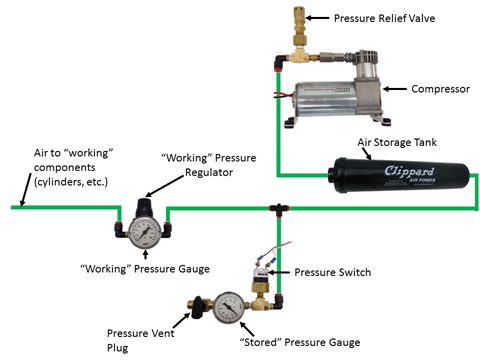

· charging pneumatics

While the TECHNICIAN may be the primary technical member of the DRIVE TEAM, all members of the DRIVE TEAM are encouraged to have knowledge of the basic functionality of the ROBOT, such as the location and operation of the main circuit breaker, connecting and resetting joysticks or gamepads from the OPERATOR CONSOLE, and removing the ROBOT from the FIELD.

POWER CELLS that leave the FIELD are placed back into the FIELD approximately at the point of exit by FIELD STAFF (REFEREES, FTAS, or other staff working around the FIELD) at the earliest safe opportunity.

Note that ROBOTS may not deliberately cause POWER CELLS to leave the FIELD (see G7).

An ARENA FAULT is not called for MATCHES that accidentally begin with an incorrect number of, incorrectly positioned, or damaged POWER CELLS. Damaged POWER CELLS are not replaced until the next ARENA reset period. DRIVE TEAMS should alert the FIELD STAFF to any missing or damaged POWER CELLS prior to the start of the MATCH.

Once the MATCH is over and the Head REFEREE determines that the FIELD is safe for FIELD STAFF and DRIVE TEAMS, they or their designee change the LED lights to green and DRIVE TEAMS may retrieve their ROBOT.

In addition to the two minutes and thirty seconds (2:30) of game play, each MATCH also has pre- and post-MATCH time for setup and reset of the ARENA. During ARENA reset, the ARENA is cleared of ROBOTS and OPERATOR CONSOLES from the MATCH that just ended. The ROBOTS and OPERATOR CONSOLES for the subsequent MATCH are loaded into the ARENA by DRIVE TEAMS at this time. FIELD STAFF also use this time to reset ARENA elements and POWER CELLS.

![]()

![]()

Safety is always paramount, and each rule below is intended to establish norms at each event that will mitigate injury risk to all participants.

Event staff have the final decision authority for all safety-related issues within a venue.

Please refer to FIRST® Robotics Competition Event Experience web page for safety, conduct, etc. rules not specific to this game or limited to MATCH play. As with all violations in this document, any Event Experience rules also carry the potential consequence of a YELLOW or RED CARD.

S1. Dangerous ROBOTS: not allowed. ROBOTS whose operation or design is dangerous or unsafe are not permitted.

Violation: If before the MATCH, the offending ROBOT will not be allowed to participate in the MATCH. If during the MATCH, the offending ROBOT will be DISABLED.

Examples include, but are not limited to:

· Uncontrolled motion that cannot be stopped by the DRIVE TEAM

· ROBOT parts “flailing” outside of the FIELD

· ROBOTS dragging their battery

· ROBOTS that consistently extend beyond the FIELD

S2. Wait for the green lights. Team members may only enter the FIELD if the POWER PORT LEDs are green, unless explicitly instructed by a REFEREE or an FTA.

Violation: Verbal warning. If repeated at any point during the event, YELLOW CARD. If egregious, RED CARD.

Egregious violations of S2 include, but are not limited to:

a. pushing passed the FIELD reset person blocking an open gate to get on the FIELD

b. ignoring a warning to not go on the FIELD

S3. Never step/jump over the guardrail. Team members may only enter or exit the FIELD through open gates.

Violation: Verbal warning. If repeated at any point during the event, YELLOW CARD.

Teams are encouraged to ensure that all members of their DRIVE TEAM are aware of this rule. It’s easy to violate, particularly when teams are doing their best to move on and off the FIELD quickly. The violations of S3 are intended to avoid nuisance penalties, but still enforce safety requirements around the FIELD. There is the potential for injury when stepping over the guardrail.

Violations of S3 apply to the entire team, not specifically to any one individual. For example, a member of team 9999 steps over the guardrail prior to MATCH 3, and a different member steps over the guardrail prior to MATCH 25. The team receives a verbal warning for the first violation and a YELLOW CARD for the second.

S4. ROBOTS, stay on the FIELD during the MATCH. ROBOTS and anything they control, e.g. a POWER CELL, may not contact anything outside the FIELD with the exception of momentary incursions into the BOTTOM PORT or LOADING BAY Chutes.

Violation: Offending ROBOT will be DISABLED.

Please be conscious of REFEREES and FIELD STAFF working around the ARENA who may be in close proximity to your ROBOT.

S5. Humans, stay off the FIELD during the MATCH. DRIVE TEAMS may not extend any body part into the FIELD during the MATCH.

Violation: YELLOW CARD

Examples of egregious violations that are likely to escalate the violation to a RED CARD include, but are not limited to, walking onto the FIELD during a MATCH or reaching into the FIELD and grabbing a ROBOT during a MATCH.

S6. Stay out of the Chutes. DRIVE TEAMS may not extend any body part into the LOADING BAY Chute. Momentary encroachment into the Chute is an exception to this rule.

Violation: FOUL

S7. Stay off the SHIELD GENERATOR and CONTROL PANELS. Team members may not sit, climb, or hang on the CONTROL PANELS, SHIELD GENERATOR, or GENERATOR SWITCH.

Violation: Verbal warning. If repeated at any point during the event, YELLOW CARD.

Teams are encouraged to ensure that all members of their DRIVE TEAM are aware of this rule. There is the potential for injury if horseplay ensues around the SHIELD GENERATOR.

Violations of this rule apply to the entire team, not specifically to any one individual. See example in the S3 blue box.

![]()

![]()

C1. Egregious or exceptional violations. Egregious behavior beyond what is listed in the rules or repeated violations of any rule or procedure during the event is prohibited.

In addition to rule violations explicitly listed in this manual and witnessed by a REFEREE, the Head REFEREE may assign a YELLOW or RED CARD for egregious ROBOT actions or team member behavior at any time during the event. This includes violations of the event rules found on the FIRST® Robotics Competition Event Experience web page

Please see YELLOW and RED CARDS for additional detail.

Violation: The Head REFEREE may assign a YELLOW or a RED CARD.

The intent of this rule is to provide the Head REFEREES the flexibility necessary to keep the event running smoothly, as well as keep the safety of all the participants as the highest priority. There are certain behaviors that automatically result in a YELLOW or RED CARD because we believe this behavior puts our community at risk. Those behaviors include, but are not limited to the list below:

a. Inappropriate behavior as outlined in the blue box of C2.

b. Jumping over the FIELD border,

c. Sitting on the SHIELD GENERATOR,

d. PINNING in excess of fifteen (15) seconds

e. Foregoing the use of the LOADING BAY rack in a way that appears to be deliberate to a REFEREE (e.g. hiding POWER CELLS or violating H10 multiple times during an event).

The Head REFEREE may assign a YELLOW or RED CARD for a single instance of a rule violation such as the examples given in items a-e above, or for multiple instances of any single rule violation.

Teams should be aware that any rule in this manual could escalate to a YELLOW or RED CARD. The HEAD REFEREE has final authority on all rules and violations at an event

C2. Be a good person. All teams must be civil toward their team members, other team members, competition personnel, FIELD STAFF, and event attendees while at a FIRST Robotics Competition event.

Violation: Behavior will be discussed with team or individual. Violations of this rule are likely to escalate to YELLOW or RED CARDS rapidly (i.e. the threshold for egregious violations is relatively low.)

Examples of inappropriate behavior include, but are not limited to, use of offensive language or other uncivil conduct.

Examples of particularly contemptible behavior that is likely to result in ARENA ejection include, but are not limited to, the following:

a. Assault, e.g. throwing something that hits another person (even if unintended)

b. Threat, e.g. saying something like “if you don’t reverse that call, I’ll make you regret it”

c. Harassment, e.g. badgering someone with no new information after a decision’s been made or a question’s been answered

d. Bullying, e.g. using body or verbal language to cause another person to feel inadequate

e. Insulting, e.g. telling someone they don’t deserve to be on a drive team

f. Swearing at another person (versus swearing under one’s breath or at one’s self)

g. Yelling at another person(s) in anger or frustration

C3. Asking other teams to throw a MATCH – not cool. A team may not encourage an ALLIANCE, of which it is not a member, to play beneath its ability.

NOTE: This rule is not intended to prevent an ALLIANCE from planning and/or executing its own strategy in a specific MATCH in which all the teams are members of the ALLIANCE.

Violation: Behavior will be discussed with team or individual. Violations of this rule are likely to escalate rapidly to YELLOW or RED CARDS and may lead to dismissal from the event (i.e. the threshold for egregious violations is relatively low.)

Example 1: A MATCH is being played by Teams A, B, and C, in which Team C is encouraged by Team D to not hang on a GENERATOR SWITCH at the end of the MATCH, resulting in Teams A, B, and C not earning a Ranking Point. Team D’s motivation for this behavior is to prevent Team A from rising in the Tournament rankings and negatively affecting Team D’s ranking. Team D has violated C3.

Example 2: A MATCH is being played by Teams A, B, and C, in which Team A is assigned to participate as a SURROGATE. Team D encourages Team A to not participate in the MATCH so that Team D gains ranking position over Teams B and C. Team D has violated C3.

FIRST® considers the action of a team influencing another team to throw a MATCH, to deliberately miss Ranking Points, etc. incompatible with FIRST values and not a strategy any team should employ.

C4. Letting someone coerce you in to throwing a MATCH – also not cool. A team, as the result of encouragement by a team not on their ALLIANCE, may not play beneath its ability.

NOTE: This rule is not intended to prevent an ALLIANCE from planning and/or executing its own strategy in a specific MATCH in which all the ALLIANCE members are participants.

Violation: Behavior will be discussed with team or individual. Violations of this rule are likely to escalate rapidly to YELLOW or RED CARDS and may lead to dismissal from the event (i.e. the threshold for egregious violations is relatively low.)

Example 1: A MATCH is being played by Teams A, B, and C. Team D requests Team C to intentionally position its CONTROL PANEL such that the color isn’t correct, resulting in Teams A, B, and C not earning a Ranking Point. Team C accepts this request from Team D. Team D’s motivation for this behavior is to prevent Team A from rising in the Tournament rankings negatively affecting Team D’s ranking. Team C has violated C4.

Example 2: A MATCH is being played by Teams A, B, and C, in which Team A is assigned to participate as a SURROGATE. Team A accepts Team D’s request to not participate in the MATCH so that Team D gains ranking position over Teams B and C. Team A has violated C4.

FIRST considers the action of a team influencing another team to throw a MATCH, to deliberately miss Ranking Points, etc. incompatible with FIRST values and not a strategy any team should employ.

C5. Enter only one (1) ROBOT. Each registered FIRST Robotics Competition team may enter only one (1) ROBOT (or ‘Robot’, a ROBOT-like assembly equipped with most of its drive base, i.e. its MAJOR MECHANISM that enables it to move around a FIELD) into a 2020 FIRST Robotics Competition Event.

“Entering” a ROBOT (or Robot) into a FIRST Robotics Competition means bringing it to or using it at the event such that it’s an aid to your team (e.g. for spare parts, judging material, or for practice).

While “most of its drive base” is a subjective assessment, for the purposes of C5, an assembly whose drive base is missing all wheels/treads, gearboxes, and belts/chains is not considered a “Robot.” If any of those components are incorporated, the assembly is now considered a “Robot.”

This rule does not prohibit teams from bringing in Robots from other FIRST programs for the purposes of awards presentations or pit displays.

Violation: Verbal warning. Egregious or repeated violations at any point during the event will be addressed by the Head REFEREE, the Lead ROBOT Inspector and/or Event Management.

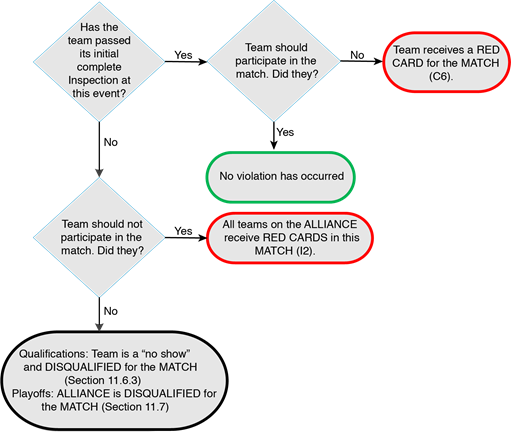

C6. Show up to your MATCHES. Upon each team’s ROBOT passing initial, complete Inspection, the team must send at least one (1) member of its DRIVE TEAM to the ARENA and participate in each of the team’s assigned Qualification and Playoff MATCHES.

Violation: If ROBOT has passed an initial, complete Inspection, RED CARD.

Figure 6‑1 MATCH participation flowchart

The team should inform the Lead Queuer if the team’s ROBOT is not able to participate.

C7. Be prompt/safe when coming to and going from the FIELD. DRIVE TEAMS may not cause significant or repeated delays during the event to the start of a MATCH, the FIELD reset after a MATCH, or continuation of MATCHES after a TIMEOUT.

Violation: If prior to the MATCH, the offending DRIVE TEAM’S ROBOT will be DISABLED. If after the MATCH, YELLOW CARD.

DRIVE TEAMS are expected to stage their ROBOTS for a MATCH, and remove it from the FIELD afterwards, safely and swiftly. Examples of violations include, but are not limited to:

a. late arrival to the FIELD (including across different MATCHES and after a FIELD or ALLIANCE TIMEOUT)

b. failing to exit the FIELD once a MATCH is ready to begin (indicated by the green LEDs have turned off)

c. installing BUMPERS, charging pneumatic systems, or any other ROBOT maintenance once on the FIELD

d. use of alignment devices that are external to the ROBOT (e.g. a DRIVE TEAM could bring and use a measuring tape, as long as there is no delay to the MATCH by doing so)

e. failing to remove OPERATING CONSOLES from the PLAYER STATIONS in a timely manner

At the conclusion of a TIMEOUT, ROBOTS are expected to be staged on the FIELD prior to the timer displaying zero (0) and ready for the MATCH to start.

C8. Don’t expect to gain by doing others harm. Strategies clearly aimed at forcing the opponent ALLIANCE to violate a rule are not in the spirit of FIRST Robotics Competition and not allowed. Rule violations forced in this manner will not result in an assignment of a penalty to the targeted ALLIANCE.

Violation: FOUL. If repeated during the MATCH, TECH FOUL.

C8 does not apply for strategies consistent with standard gameplay, for example, a Blue ALLIANCE ROBOT contacts a Red ALLIANCE ROBOT in the Blue ALLIANCE’S LOADING ZONE.

C8 requires an intentional act with limited or no opportunity for the TEAM being acted on to avoid the penalty, such as:

a. a Blue ALLIANCE ROBOT forcing a Red ALLIANCE ROBOT to have greater than momentary CONTROL of five (5) POWER CELLS.

b. a Blue ALLIANCE ROBOT pushing a Red ALLIANCE ROBOT from fully outside the Blue ALLIANCE TRENCH RUN into the Blue ALLIANCE CONTROL PANEL.

C9. One student, one Head REFEREE. A team may only send one (1) pre-college student from its DRIVE TEAM to address the Head REFEREE.

Violation: The Head REFEREE will not address additional, non-compliant team members or peripheral conversations.

Please see REFEREE Interaction for more information about process and expectations.

C10. Plug in to/be in your PLAYER STATION. The OPERATOR CONSOLE must be used in the PLAYER STATION to which the team is assigned, as indicated on the team sign.

Violation: The MATCH will not start until the situation is corrected. If during a MATCH, DISABLED.

One intent of C10 is to prevent unsafe situations where long tethers to OPERATOR CONSOLE devices increase tripping hazards as the operator moves about the ALLIANCE STATION. In the interest of avoiding nuisance penalties associated with an operator stepping outside of a prescribed area, we prefer to offer a general guideline as to what it means to use the OPERATOR CONSOLE in the ALLIANCE STATION. Provided the operator is within close proximity of their PLAYER STATION, there will be no repercussions. However, an operator located more than approximately ½ PLAYER STATION width away from their own PLAYER STATION, is likely violating C10.

![]()

G1. Know your ROBOT setup. When placed on the FIELD for a MATCH, each ROBOT must be:

A. in compliance with all ROBOT rules, i.e. has passed Inspection (for exceptions regarding Practice MATCHES, see Inspection & Eligibility Rules),

B. the only team-provided item left on the FIELD by the DRIVE TEAM,

C. confined to its STARTING CONFIGURATION,

D. positioned such that its BUMPERS are intersecting the infinite vertical volume created by the corresponding ALLIANCE’S INITIATION LINE, and

E. fully and solely supporting not more than three (3) POWER CELLS (as described in Setup.)

Violation: If fix is a quick remedy, the MATCH won’t start until all requirements are met. If it is not a quick remedy the offending ROBOT will be DISABLED and, at the discretion of the Head REFEREE, must be re-inspected.

Teams are encouraged to position ROBOTS such that it is clear to REFEREES that G1-D is not violated.

If a ROBOT is BYPASSED prior to the start of the MATCH, the DRIVE TEAM may not remove the ROBOT from the FIELD without permission from the Head REFEREE or the FIRST Technical Advisor (FTA).

G2. Teams may not enable their ROBOTS on the FIELD. Teams may not tether to the ROBOT while on the FIELD except in special circumstances (e.g. during TIMEOUTS, after Opening Ceremonies, before an immediate MATCH replay, etc.) and with the express permission from the FTA or a REFEREE.

Violation: YELLOW CARD.

FMS will not enable ROBOTS after the conclusion of the MATCH.

Tethering includes any wired or wireless connection used to electrically energize and/or control elements on the ROBOT. The safety of teams and volunteers in close proximity to ROBOTS and ARENA elements on the FIELD is of the utmost importance, therefore ROBOTS or ROBOT COMPONENTS may not be enabled in any way on the FIELD once the MATCH has concluded.

ROBOTS need to be safely transported off the FIELD and back to the pits after the MATCH, and there may be bystanders, doorways or height restrictions along the route.

G3. During AUTO, no defense. During AUTO, a ROBOT’s BUMPERS may not break the plane of their ALLIANCE’s SECTOR (see Figure 3‑3.)

Violation: FOUL. If contact with an opponent ROBOT, either directly or transitively through another ROBOT or POWER CELL, TECH FOUL per instance.

G4. During AUTO, behind the lines. During AUTO, DRIVE TEAM members in ALLIANCE STATIONS may not contact anything in front of the STARTING LINES, unless for personal or equipment safety.

Violation: FOUL per item contacted.